|

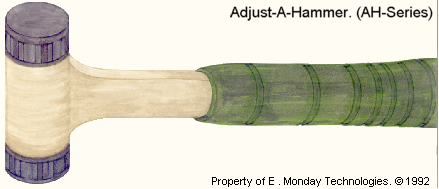

| The Removable Heads pounding hammer group was one of the first few products I designed in 1992, and attempted to sell it just when it was a sketch, and completely designed/engineered tool to some hand-held tools manufacturers in order to raise some money to setup E . Monday Technologies other products. Why would anyone think of a hammer that is adjustable and suitable for serious pounding? especially when the hammer has not evolved into anything besides from stone or heavy wood to metal head with anything to hold it as handle for centuries. Interestingly as it may sound, this hammer started out in life at E . Monday Technologies as a versatile adjustable piece of equipment whose purpose in life is to bring new excitement to a tool whose use is indispensable, but never have had any fun, which is what led to the Fixed Adjustable heads. More advanced models of this interesting tool are in place, available in metal, plastic and wood and hide heads. |

|

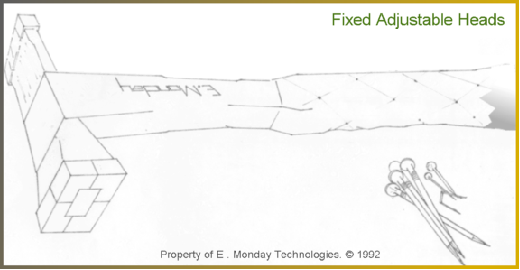

| Fixed Adjustable Heads was a radical as it could be then and perhaps now, the buzz word that most mechanical engineers were tolled with at the time was, there is an adjustable hammer that they don't know about and whenever necessary can't phantom that this guy is working on. I heard it was difficult for some to imagine, let alone to think of the engineering; to confirm, several products showed up in the market that had sought to replicate the functions of adjust-a-hammer including some design cues to demonstrate they can get it done and cashed-in on whatever unit they could sell in the market. This model's objective was to have one hammer that can transform into varying sizes based on the application need, with its individual adjustable heads, which counts as five heads. The design logic was tasking given the engineering application, which is to drive nails into hard surfaces and not fail. When it was done as expected the simulation of its performance did not guarantee the kind of excitement I get with products for critical mission that gets things done, it can drive up to 3/8" nails into most surfaces, while the individual heads, or in combination can drive nails under that. The adjustment to different sizes could become clumsy in some fast pace situation and that's why it will not be release anytime soon, but the exercise did take us to power nailer whose heads are driven by air because more force to weight ratio was sought, and that's how the power nailers in the market today came about; weight that create fatigue was an issue, which Eghe Tools' AH-Series hammers has sought to defeat and the mission is successful. |

|

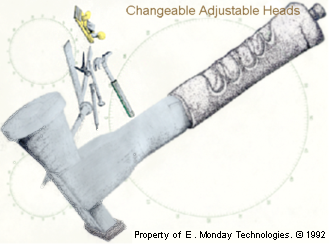

| The packaging of this design is carried over to the advance AH-Series hammer models Eghe Tools will release to the market, while this round head design essentially is the same as the Fixed Adjustable Heads, it has something special, which include fitted rubber caps, marking pencil installed at the butt of the handle for user to mark surfaces with, and other features. This design characteristic is carried into the designs of AH-Series as stated above. |

|

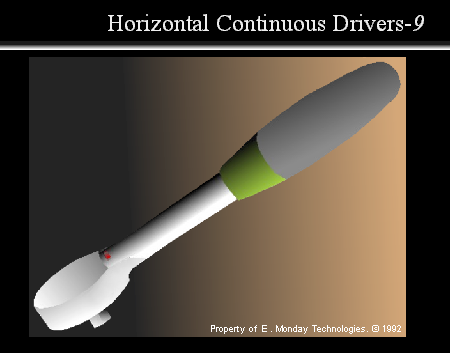

| Horizontal Continuous Driver was the second piece of tool that was designed at E . Monday Technologies, the particular formula for this design came about when I was trying to fix a Bell & Howell fax machine with some tricky assembly. Getting to some recessed screws in places with no room to maneuver, even with an Off-Set screw driver got me to think of a tool that don't exist to accomplish this task, I did not want to take the machine apart to check the condition of the part I knew might be the problem. Being that it will have to be a specialize tool, I asked the traveling MAC Tools vending operator who showed me his entire inventory in order for me to believe that he never heard or knew of any body that has this type of a tool, which screws and un-screw by turning the handle. So I proceeded to design this product and all associated products and called it Continuous Driver. A few manufacturers who remembers not paying anything to have it on their product line has been earning income with this. |

|

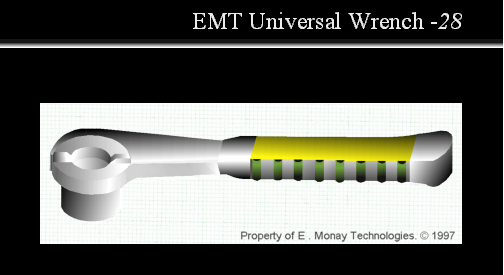

| EMT Universal Wrench was design to show off to Snap-Tools because of their system of innovation, their product line is way more elaborate than that of Eghe Tools because they have complete line of automotive servicing tools, a lot of which they designed with service technicians telling them of a task they are working on and don't have the right type of tools to go the quick way, which means, what we will design will have to be what they and other serious tools' company don't have, this particular tool as Snap-On knows kind of gave us an entry- not a real one into automotive tools, it is a pass-through, ratcheting tool with a enough torque to handle bolts and nuts their ratchet wrench can handle and that still don't make us competitors, but it was fun to harass them with something. |

| ** This tool, AH-Series Hammers and a few other tools or related product are what Sears Roebuck manufactured and sold without the consent of E . Monday Technologies. Featured design is a right-handed model, but the actual is for both hands. |

Eghe Tools Company has not made final decision to partner with any company at this time, but has interested that thought to a company(ies) whose interest directly aligns with that of Eghe Tools Company.

Since the idea of mergers and acquisitions is often times evaluated, either to broaden the product line, or to achieve a more strategic market position any company whose interest aligns with that of Eghe Tools Company may send information to Eghe Tools , Please do not send any engineering drawings, or a descriptive literature of any product, such activity is not being managed at this time.

Such product may not be an improved version of an existing product from either the company you work for, or any other company. You may consult the original manufacturing companies of the product(s) for assistance. Any company currently engaged in infringement, or being accused of such may not become interested in this business opportunities.

| Innovation: |

At Eghe Tools Company to stay ahead and with the game requires persistent evaluation and update of the product line, processes, material and parts technology, which affects the way manufacturing companies does business, even though, our activities does not currently include manufacturing and distribution of our products, the management is not different from companies whose activities include manufacturing and distribution. We have to track the health and progress of industries whose activities controls the means available to plan and execute, as well as, information the end users are managing, which controls the products we can deliver to the market. In this arrangement, new products are designed, existing products are updated or scrapped because of obsolesce; over 95% of the products we have are still current with more under development. |

| Logo and Transitions |

The transition to the new logo was to commence 3-5 years after we have shipped our first product, to comfortably reflect the span and organization of the business. Its design incorporates a pair of green and The previous logo shown here was more to highlight the particular job Eghe Tools has, which is still what it will increase its operation with, the logo image purposely remind technicians of a Micrometer the measuring tool, ruggedness with the nut and foundry operation with the orange extruded bar, performing surface metrology on a planet. |

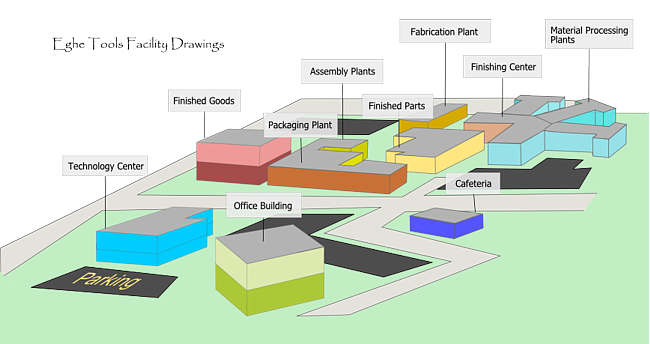

| Site Layout Plan |

|

| Tasks Tool in product line performs |

| Eghe Tools Company design, manufacture and distribute tools to Woodworking, Metal, Wood and Plastic Finishing, Hobbyist, Fabrication, Home Improvements, Framing, and Material processing industry etc. Our product line is currently not very active for automotive and similar equipment repairs, but does have some products that could be used for such because of their versatility. |

Eghe Tools Company that has been working, or considering various options for financing also solicited both Private and Institutional investors, as well as the Investment Revenue Bond to raise capital to initiate an effective increase operations. It has been working with the state in which Eghe Tools Company is locating to have that aspect properly situated. A few individual has expressed interest to acquire.

Further information regarding the issue date, and the investment company responsible for distribution, or sale of the bonds will be posted on this page. Professional investors requesting investment relevant information of Eghe Tools Company may go to the contact page directory to initiates communication to Eghe Tools Company, or use the Contact Info Tab.Eghe Tools Company will recruit needed personnel independent of the E . Monday Technologies and other related companies.

| General Contact Information. | ||

| Request/Inquire: | Product Info | |

| Send: | Solutions Feed back | |

| Response Party: | E . Monday Uyigue | |

| Phone: | 1-855-771-0475 | |

| emuyigue@emondaytechnologies.com | ||

| Other Inquiry: | admin@emondaytechnologies.com | |